-evolving landscape of water treatment technologies, tube settler media has emerged as a pivotal component for enhancing sedimentation processes in both municipal and industrial applications. As environmental engineers face increasingly stringent regulations and growing demands for efficient water treatment, understanding the mechanisms, advantages, and comparisons to other technologies becomes essential for effective system design and operation. This article delves into how tube settler media works, its key advantages, and how it stacks up against other biofilm technologies in the realm of water treatment.

How Tube Settler Media Works

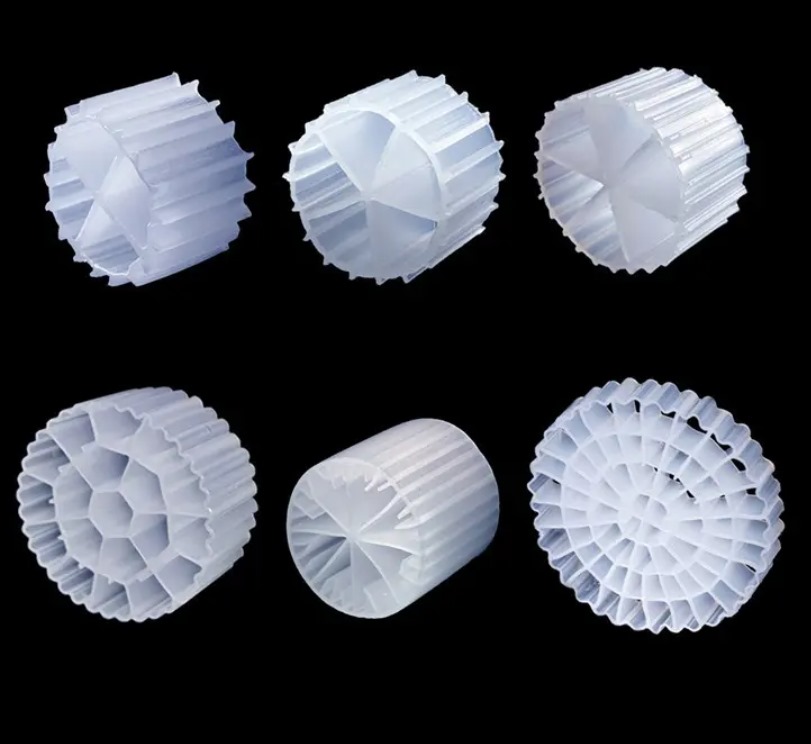

Tube settler media, often utilized in the sedimentation stage of water treatment, consists of a series of inclined tubes or channels that facilitate the rapid settlement of suspended solids. The design of the tube settler media is tailored to maximize the effective surface area available for sedimentation while minimizing the overall footprint of the treatment system.

1. Mechanism of Action

The operation of tube settler media is based on the principles of gravity sedimentation. When wastewater or raw water enters the clarifier, it flows through the inclined tubes. The design typically features tubes arranged at a 60-degree angle, allowing for an efficient downward flow of settled particles.

- Increased Surface Area: The inclined tubes create an extensive surface area, enabling particles to collide with the tube walls and settle more effectively. This design significantly enhances the settling rate compared to traditional sedimentation basins.

- Gravity-Driven Settling: As water flows through the tubes, suspended solids are subjected to gravitational forces, promoting their downward movement. The longer path created by the inclined design allows for greater interaction between the water and settling particles.

- Effluent Removal: The clarified water exits at the top of the clarifier, while the settled solids accumulate at the bottom, where they can be periodically removed for further treatment or disposal.

2. Compact Design

One of the key features of tube settler media is its compact design, which allows for the optimization of sedimentation processes without requiring extensive modifications to existing infrastructure. This space-saving feature is particularly beneficial for retrofitting older treatment plants or in urban settings where space is limited.

Advantages of Tube Settler Media

The use of tube settler media in water treatment systems offers several advantages that make it a compelling choice for environmental engineers.

1. Enhanced Sedimentation Efficiency

Tube settler media significantly improves the efficiency of sedimentation processes. By maximizing the effective settling area, the technology allows for higher flow rates and improved removal of suspended solids. This leads to better water quality and reduced downstream treatment requirements.

2. Space Optimization

Due to their compact design, tube settlers require less physical space compared to traditional clarifiers. This is especially advantageous for municipalities and industries facing space constraints or looking to upgrade existing facilities without extensive construction. The ability to enhance sedimentation performance without expanding the treatment footprint can lead to substantial cost savings.

3. Low Maintenance Needs

Tube settler media is designed for ease of maintenance. With fewer mechanical components and a robust construction, these systems require less frequent servicing than other technologies. Periodic inspections and cleaning of the tubes are typically sufficient to maintain optimal performance, resulting in reduced operational downtime and lower maintenance costs.

4. Cost-Effectiveness

Investing in tube settler media can lead to long-term cost savings for water treatment facilities. The combination of improved efficiency, reduced maintenance needs, and space optimization contributes to a favorable return on investment. Additionally, the enhanced quality of the effluent can decrease the need for downstream filtration and disinfection processes, further lowering operational expenses.

5. Versatility Across Applications

Tube settler media is versatile and can be applied in various water and wastewater treatment scenarios, including municipal drinking water treatment, industrial process water treatment, and stormwater management. Its adaptability makes it a valuable addition to a wide range of treatment processes, catering to the specific needs of each facility.

Comparison to Other Biofilm Technologies

While tube settler media excels in sedimentation processes, it is essential to compare its functionalities with other biofilm-based treatment technologies, such as Moving Bed Biofilm Reactors (MBBRs) and Integrated Fixed-Film Activated Sludge (IFAS) systems.

1. Tube Settler Media vs. MBBR Systems

MBBRs utilize plastic media to cultivate biofilm, which treats organic pollutants through microbial activity. In contrast, tube settler media focuses on the physical separation of suspended solids.

- Functionality: Tube settlers are primarily designed for sedimentation, while MBBRs serve as biological reactors for treating organic contaminants.

- Maintenance: Tube settlers require less maintenance due to their mechanical design, whereas MBBRs necessitate careful management of biofilm growth, which can require more frequent monitoring and intervention.

- Application: Tube settlers are typically employed as a preliminary or secondary treatment step, while MBBRs are used in biochemical processes, often necessitating post-treatment clarification.

2. Tube Settler Media vs. IFAS Systems

IFAS systems combine traditional activated sludge processes with fixed-film carriers for enhanced biological treatment. Similar to MBBRs, IFAS systems are primarily focused on biological processes but include components for sedimentation.

- Operational Complexity: IFAS systems tend to be more complex due to the need for aeration and management of both suspended and attached biomass. In contrast, tube settler media is simpler and focuses on sedimentation without the complexities of biological treatment management.

- Clarification Role: Tube settler media serves as a dedicated clarification step, while IFAS systems require additional clarification stages to ensure effluent quality. This separation allows for easier operation and maintenance of tube settlers.

3. Tube Settler Media vs. Dissolved Air Flotation (DAF)

Dissolved Air Flotation systems utilize microbubbles to float suspended solids to the surface, allowing for their removal.

- Separation Mechanism: While tube settlers rely on gravity for sedimentation, DAF systems employ flotation. Each method has its strengths depending on the specific water quality issues being addressed.

- Energy Use: Tube settlers are generally more energy-efficient than DAF systems, which require pumps and compressors to generate air bubbles.

- Application Suitability: Tube settler media is often more effective for handling high concentrations of suspended solids, whereas DAF is better suited for applications requiring oil and grease removal.

Conclusion

In 2024, tube settler media stands out as an efficient, cost-effective solution for enhancing sedimentation processes in water treatment systems. By maximizing settling efficiency while minimizing space requirements and maintenance needs, tube settlers provide environmental engineers with a reliable tool for meeting modern water quality standards.

As water treatment challenges continue to evolve, the adoption of innovative technologies such as tube settler media will be crucial for ensuring sustainable and efficient operations in the water treatment sector. Environmental engineers tasked with optimizing treatment processes can find in tube settler media a valuable ally in their efforts to deliver high-quality, clarified water